Rumble strips are a crucial safety feature installed on roads and highways. These textured patterns serve a significant purpose: to alert drivers when they are drifting out of their lane or approaching a dangerous area. In this guide, we’ll delve into how rumble strips are installed correctly and how these installations enhance road safety. Understanding this process is essential not only for road workers but also for drivers who benefit from these tactile feedback measures every day.

What Are Rumble Strips?

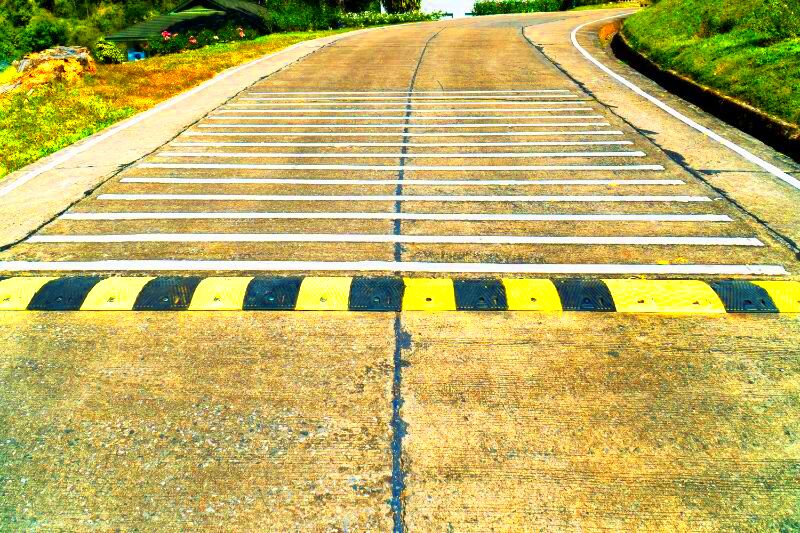

Rumble strips are patterned grooves or raised designs along the road surface, primarily designed to warn drivers through sound and vibration. When a vehicle runs over these strips, they produce a rumbling noise and tactile feedback that can be quite noticeable, especially at higher speeds. But what exactly are the different types of rumble strips, and how do they function? Let’s break it down.

- Shoulder Rumble Strips: Often found along the edge of the road, these strips alert drivers when they’re veering off the pavement.

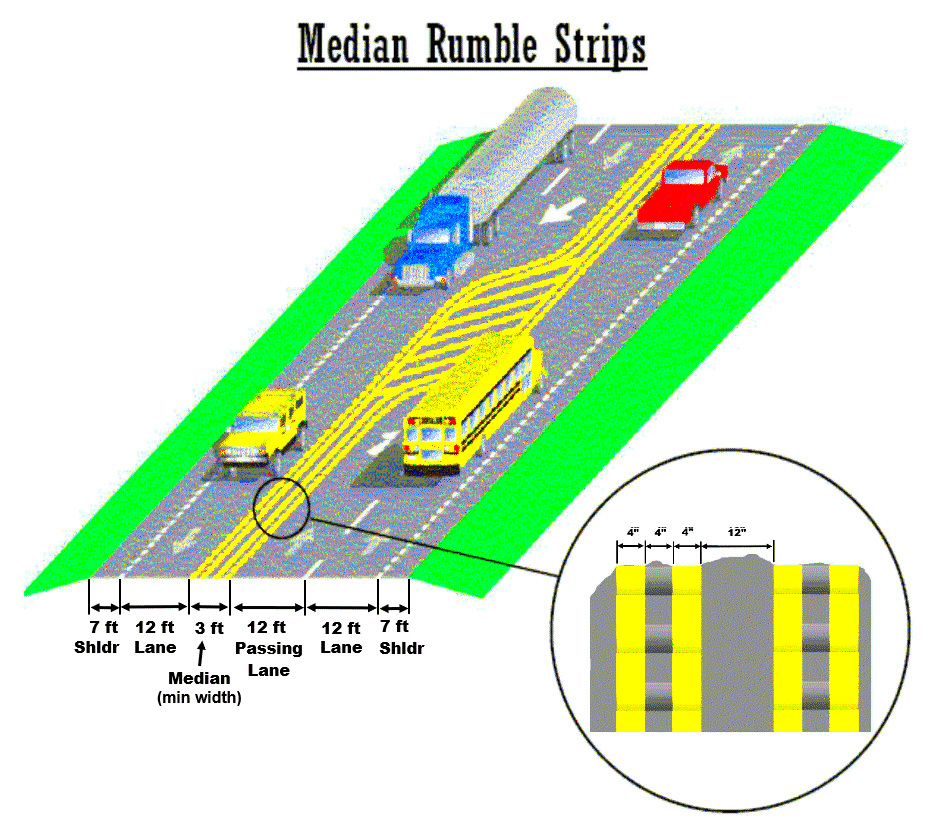

- Centerline Rumble Strips: Installed along the center line of divided highways, these help prevent head-on collisions by warning drivers who drift into oncoming traffic.

- Transverse Rumble Strips: Typically placed at intersections or pedestrian crossings, these strips help in reducing speed and increasing awareness of potential hazards.

In summary, rumble strips are more than just bumps on the road; they play an essential role in ensuring safer driving conditions by providing both auditory and sensory warnings to drivers. Their placement and installation should always adhere to specific best practices to maximize effectiveness.

Read This: How Many Times Has John Cena Won the Royal Rumble Throughout His Career?

Types of Rumble Strips

When it comes to rumble strips, it’s essential to know that they aren’t all made the same. Different types serve different purposes and are tailored to various road conditions. Let’s delve into the key types of rumble strips you’ll encounter on roadways:

- Textured Rumble Strips: These are typically placed on the shoulder or center line of roads and create a noticeable vibration and sound when a vehicle drives over them. They are excellent for alerting drivers who may be drifting out of their lane.

- Ground-In Rumble Strips: Ground-in rumble strips are cut directly into the pavement. They provide a more permanent solution and are often less noisy than their surface-mounted counterparts. They’re an excellent choice for long-lasting durability.

- Raised Rumble Strips: This type is made from rubber or plastic and is installed on the pavement's surface. They are more visible and provide a clearer warning signal to drivers but can be smoother during rain, so they might not be as effective in wet conditions.

- Shoulder Rumble Strips: Placed along the edges of the road, shoulder rumble strips alert drivers when they are veering off the side of the road. They are important for preventing run-off-road crashes, especially in rural areas.

- Centerline Rumble Strips: Installed along the centerline of two-way roads, these are great for reducing head-on collisions. They make a significant noise and vibration that warns drivers when they are straying into oncoming traffic.

Choosing the right type of rumble strip can greatly enhance safety on the road. Each has its specific use case, so understanding their differences is crucial for effective implementation.

Read This: Who Won the Royal Rumble This Year?

Benefits of Rumble Strips

Rumble strips are more than just grooves cut into the pavement; they serve several crucial functions. Let's explore some of the most significant benefits of installing rumble strips:

| Benefit | Description |

|---|---|

| Increased Safety | Rumble strips significantly reduce the risk of accidents by alerting drivers who might be drifting out of their lane. This is particularly vital on highways and rural roads. |

| Crash Prevention | Studies have shown that rumble strips can lead to a reduction in fatal crashes and serious injuries, particularly those resulting from run-off-road and head-on collisions. |

| Cost-Effectiveness | Although the initial installation cost exists, rumble strips are relatively inexpensive compared to the potential costs associated with accidents, including medical, legal, and repair expenses. |

| Driver Awareness | They serve as a reminder for drivers to remain attentive, particularly in areas known for accidents or distractions, helping to foster a greater sense of vigilance. |

| Easy Implementation | Most rumble strips can be installed quickly and with minimal disruption to traffic, making them an excellent solution for immediate safety improvements. |

In summary, the benefits of rumble strips far outweigh the costs. They play a vital role in enhancing road safety while also being a cost-effective solution for preventing accidents. Understanding these advantages can help transportation officials make informed decisions about their implementation.

Read This: How to Get Rid of Super Rumble on Instagram Stories

Preparation for Installation

Before diving into the installation of rumble strips, it's crucial to lay the groundwork for success. This preparation not only ensures safety but also enhances the effectiveness of the rumble strips.

Here are some important steps to follow:

- Site Assessment: Start by assessing the location where the rumble strips will be installed. Look for areas with a history of accidents or where driver alertness is especially vital, such as near schools, pedestrian crossings, and sharp curves. Consider factors like traffic volume and speed limits.

- Planning & Design: Develop a comprehensive plan that includes the type of rumble strips (e.g., milled or raised), dimensions, and layout. Consult with local authorities or traffic engineers to ensure compliance with regulations.

- Weather Considerations: Weather conditions can impact the installation process. Aim to install rumble strips during dry weather, as moisture can affect adhesion and the durability of materials used.

- Clearing the Area: Ensure the installation site is clear of debris, vegetation, and any potential obstructions. This preparation step will allow for a smoother installation and reduce the risk of accidents.

- Gather Necessary Equipment: Equip yourself with the right tools and materials. Some essential items may include a milling machine (for milled rumble strips), paint or adhesive, safety cones, and reflective materials.

Taking the time to prepare effectively sets the stage for a successful installation and ultimately contributes to the safety and awareness of drivers on the road.

Read This: What Episode Is the Rumbling in Attack on Titan? Key Details Explained

Steps for Installing Rumble Strips

With the preparation complete, it's time to roll up those sleeves and get to work! Installing rumble strips, while straightforward, requires precision and adherence to best practices. Here’s a step-by-step guide to ensure everything goes smoothly:

- Marking the Location: Begin by marking the exact locations where the rumble strips will be placed. Use chalk or spray paint to outline their dimensions based on your earlier planning.

- Engage Equipment Appropriately: If you're using milled rumble strips, operate the milling machine along the marked lines. Make sure to follow specified depth and width measurements to maintain uniformity. If you're opting for raised strips, prepare the road with the necessary adhesive.

- Curing Time: After installing milled strips or applying raised strips with adhesive, allow the material to cure properly. Follow the manufacturer's recommendations for drying time, which can vary based on weather and product type.

- Signage Installation: After the rumble strips are set, it’s essential to install clear signage around the area. Signs should indicate that rumble strips are present, providing warnings for drivers. This step is crucial for enhancing visibility and awareness.

- Final Inspection: Before opening the area to traffic, perform a final inspection. Ensure that the strips are secure and that the area is safe for vehicles. Evaluate if additional road markings or reflective materials are necessary for heightened visibility.

- Monitor Performance: After installation, observe the performance of the rumble strips. Pay attention to any feedback from drivers and adjust as necessary. Continuous monitoring can help you assess the effectiveness of the strips and make improvements if required.

By adhering to these steps, you’ll ensure that your rumble strips are installed correctly and function effectively, helping to keep roads safer for everyone!

Read This: How Many Rumble Bees Were Made and What They Mean for the Game

7. Safety Considerations During Installation

When it comes to installing rumble strips, safety should always be a top priority. Imagine you're out there on the road, working hard to improve safety for drivers and pedestrians alike. It’s essential to take precautions to ensure not only your safety but also that of the passing motorists. Here are some vital safety considerations to keep in mind:

- Traffic Control: Before you start the installation process, set up proper traffic control measures. Use cones, flags, and signs to alert drivers of ongoing work ahead. This reduces the risk of accidents and ensures the safety of your crew.

- Personal Protective Equipment (PPE): Wearing the right gear is crucial. Make sure all crew members don appropriate PPE, such as hard hats, reflective vests, gloves, and sturdy footwear to protect against any hazards.

- Weather Conditions: Always check the weather before heading out. Rain, wind, or extreme temperatures can impact your ability to work safely and may jeopardize the quality of the installation.

- Team Communication: Have a clear communication plan. Use radios or hand signals to ensure that everyone knows what’s happening on-site, especially when heavy machinery is involved.

- Proper Equipment Use: Ensure that all equipment is in good working condition. Regular maintenance checks will help avoid breakdowns, which can pose safety risks on the job.

By considering these safety aspects, you can help create a work environment that minimizes risks and maximizes safety, ensuring a smooth installation of rumble strips.

Read This: How to Play Royal Rumble in WWE 2K23 and Eliminate Your Opponents

8. Maintenance of Rumble Strips

Once your rumble strips are installed, the work isn’t entirely done! Regular maintenance is essential to ensure they continue to perform effectively and contribute to road safety. Let’s explore some critical components of rumble strip maintenance:

- Visual Inspections: Perform periodic visual checks of the rumble strips to assess their condition. Look for signs of wear, fading, or damage. The sooner you catch a problem, the easier it will be to address it.

- Cleaning: Keep rumble strips clean from debris, dirt, and growing vegetation. Sometimes, a simple cleaning can enhance their visibility and effectiveness. Depending on the area, you might need to use a high-pressure washer or a broom.

- Repairing Damages: If any rumble strips appear to be damaged or worn down, don’t ignore them. Prompt repairs reduce the risk of ineffective rumble strips, which can compromise safety. You can often fill in or replace damaged sections.

- Surveying Performance: Regularly assess the performance of rumble strips and gather feedback from local road users. Their insights can help you determine if adjustments or maintenance work is needed.

Maintaining rumble strips is all about ensuring that they serve their purpose—alerting drivers and enhancing safety on the roads! A little upkeep goes a long way in preserving their effectiveness.

Read This: Who Won the 1993 Royal Rumble Match?

Common Mistakes to Avoid

When it comes to installing rumble strips, even the most experienced contractors can run into pitfalls. It's crucial to avoid these common mistakes to ensure that the strips serve their purpose effectively and safely. Let's dive into some pitfalls you should keep an eye out for:

- Incorrect Placement: One of the biggest mistakes is failing to place rumble strips in the correct location. They should be strategically positioned to alert drivers at critical points, such as near intersections or pedestrian crossings. If installed too far from where the alert is needed, their effectiveness diminishes.

- Poor Surface Preparation: A common misstep is neglecting the road surface before installation. If the surface is not clean and smooth, the adhesive may fail, causing the strips to peel off prematurely. Always ensure the area is prepped and free of debris.

- Ignoring Local Guidelines: Each region may have specific regulations regarding the installation of rumble strips. Failing to adhere to these guidelines can result in legal complications and safety hazards. It's essential to research and comply with local traffic control standards.

- Overlooking Maintenance: After installation, some ignore the need for ongoing maintenance. Weather and wear can affect the rumble strips’ functionality over time. Regular inspections and timely repairs are crucial for keeping them effective.

- Using Incompatible Materials: Not all materials are suitable for all surfaces. Ensure that the materials used for the rumble strips match the road type to avoid issues like cracking or flaking.

Avoiding these mistakes can significantly enhance the effectiveness of rumble strips, leading to safer driving environments. Always take your time during the planning and installation phases to ensure that the end result is beneficial for everyone on the road.

Read This: Can You Get Shinies in Pokémon Rumble World? Tips for Finding Rare Pokémon

Conclusion

In wrapping up our journey through the installation of rumble strips, it's clear that proper installation is crucial for maximizing road safety and reducing accidents. Rumble strips not only serve as physical barriers to prevent drifting but also provide auditory and tactile feedback to alert drivers who may be distracted. Here’s a quick recap of what we've discussed:

- Understanding the different types of rumble strips and their appropriate applications.

- The step-by-step process of installation to ensure effectiveness and durability.

- Common mistakes to avoid during the installation to enhance safety.

Rumble strips play an essential role in roadway safety, but their efficacy hinges on proper planning, execution, and maintenance. By avoiding common pitfalls and adhering to best practices, communities can significantly enhance the safety of their roads. Remember, it's not just about installing rumble strips; it's about creating a safer environment for all road users. So, whether you're managing roads or just advocating for safer driving conditions, staying informed about installation best practices is key to making a difference. Here’s to safer journeys ahead!

Related Tags